Steel mills are among the most hazardous industrial environments in the world—blazing temperatures, intense noise, flying slag, high-voltage equipment, and the constant motion of heavy machinery combine to create a demanding and dangerous workplace. In these extreme conditions, clear visual and audible communication is not just helpful—it’s essential for protecting workers, equipment, and operations.

TOMAR Electronics offers a comprehensive line of signaling and industrial lighting solutions specifically engineered for the challenges of steel manufacturing. From furnace areas to crane operations and tunnel systems, TOMAR’s rugged, high-performance equipment is deployed across steel plants nationwide. Here’s how TOMAR’s products provide real-world solutions for today’s steel producers.

Understanding the Hazards of Steel Manufacturing

Steel production involves several high-risk processes, from raw material handling to molten metal transfer and high-temperature furnace operations. Key hazards include:

- Molten metal and slag that pose immediate threats to personnel.

- Large cranes and moving molds that create crush and collision risks.

- High-pressure systems and volatile gases like oxygen, which can cause explosions if mishandled.

- Noise levels frequently exceeding 100 decibels, making audible-only alarms ineffective.

These risks demand specialized, durable signaling systems beyond standard industrial safety measures.

The Problem with Traditional Lighting and Signals in Steel Mills

The Problem with Traditional Lighting and Signals in Steel Mills

Many steel facilities still rely on outdated incandescent or metal halide lighting. However, these older technologies fall short in several critical ways:

- Heat Tolerance: Traditional lighting cannot survive ambient temperatures of 60–75°C common near furnaces.

- Maintenance Downtime: Frequent bulb and fixture failures increase the risk of accidents and costly shutdowns.

- Limited Signal Visibility: Incandescent warning lights struggle with vibration resistance and deliver significantly less light output than modern LED strobes.

Furnace Area Safety: Preventing Hazards at the Core

Furnaces—whether gas-fired or electric—are central to steel manufacturing and come with unique hazards. Gas furnaces require flameout alarms to prevent gas buildup, while electric furnaces demand high-voltage warning signals to alert personnel when circuits are active.

TOMAR’s power alarm systems, such as the Model 1000-120, are built to signal clearly even in loud, chaotic environments. These alarms can be configured to notify teams when power must remain off during maintenance, preventing accidental reactivation and catastrophic injury.

Molten Metal Handling: Visual Warnings in Critical Zones

For facilities with non-standard electrical systems, TOMAR offers specialty models like:

Both are designed to operate at 250VDC, a common requirement in older steel plant infrastructure.

Process Area Alarms & Automation Integration

Modern steel mills increasingly rely on automated systems that demand real-time signaling integration. TOMAR’s solutions support sensor-triggered alerts for moving steel buckets, conveyor systems, and crane operations.

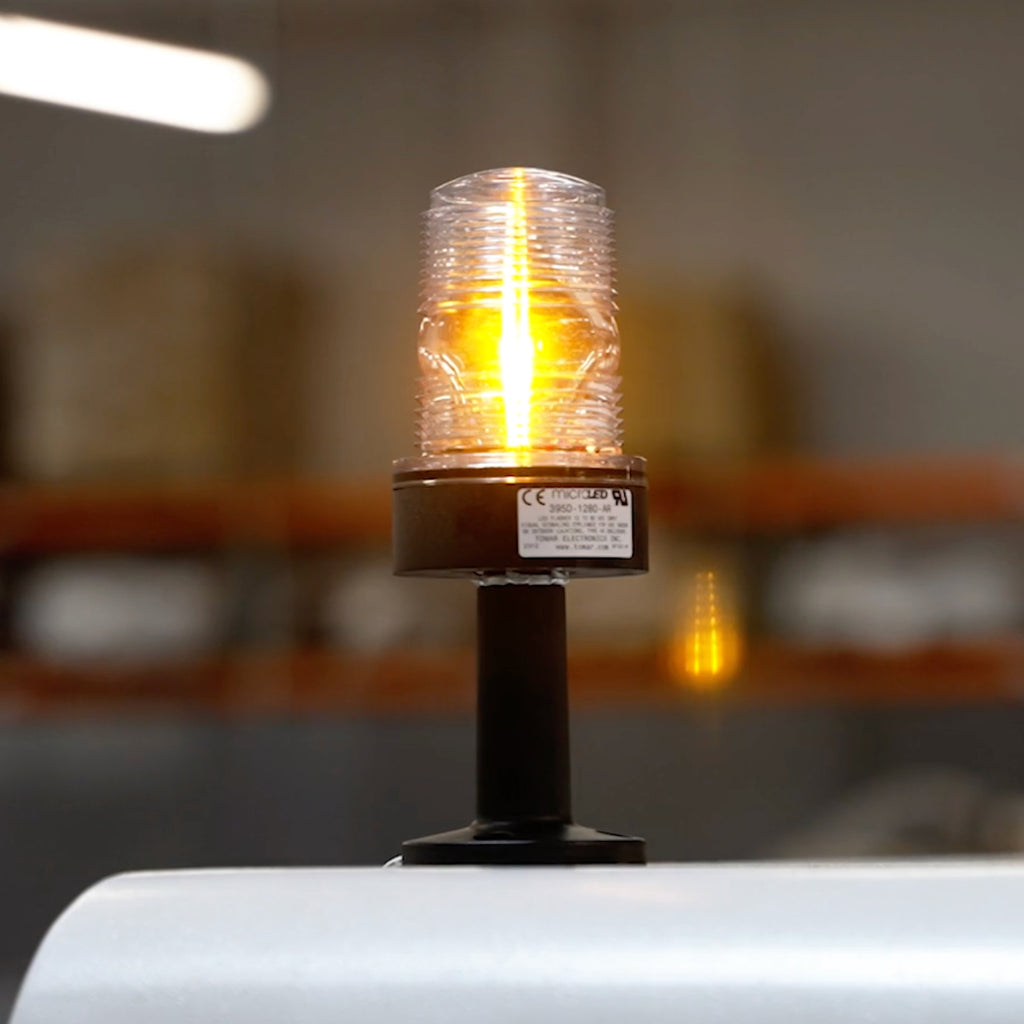

In process control environments, TOMAR’s Microstack, Microstrobe, and MicroLED systems offer compact, modular signaling that integrates seamlessly with process monitoring systems. These systems provide visual updates on temperature, pressure, and conveyor speed, enhancing response time and plant-wide safety.

Hazardous Storage Areas: Signaling in Coke, Gas, and Chemical Zones

Storage areas in steel mills pose additional safety challenges due to the presence of:

- Coke batteries

- Gas injection systems

- Oxygen and chemical storage tanks

TOMAR’s explosion-proof alarms and high-visibility visual indicators are engineered to withstand volatile environments and ensure personnel safety.

For chemical processing and cleaning zones—often classified as Division 2 hazardous locations—TOMAR provides specialized alarms for hazardous vapor and spill detection. These systems are vital in under-tunnel corridors, degreasing zones, and confined utility spaces.

Built for the Realities of Steel Manufacturing

TOMAR’s products go far beyond simple warning or strobe lights—they’re engineered safety systems designed for the extreme conditions found in steel production. The product line includes:

From furnace rooms to crane bays, TOMAR provides steel plants with reliable, durable, and high-performance signaling equipment to support both safety and productivity.

Why Steel Mills Trust TOMAR

Whether you’re:

- Upgrading outdated infrastructure

- Implementing new automation systems

- Enhancing workplace safety

TOMAR Electronics has a proven solution for every application in your facility.

From the furnace to the finish line, TOMAR helps steel producers stay safe, stay compliant, and stay productive—day in and day out.