Automotive manufacturing facilities are fast-paced environments filled with complex machinery, robotic systems, and pressurized operations. From stamping presses and robotic arms to paint booths and fuel depots, each area presents a unique set of hazards. These challenges demand a high level of visual and audible signaling to keep processes running efficiently while protecting operators and maintenance crews.

TOMAR Electronics delivers process-driven signaling and illumination solutions designed for the speed, precision, and scale of automotive manufacturing. Whether mounted on control panels, production lines, or robotic cells, TOMAR’s audible and visual signaling devices help automotive plants increase productivity, maintain safety compliance, and reduce response times during faults or emergencies.

Engineering Integration Across Plant Safety and Process Systems

TOMAR’s signaling systems are built to integrate with the core processes of automotive production. These systems can be deployed across:

- Robotic Welding and Assembly Cells

- Paint Booths and Fuel Depots (hazardous-rated areas)

- Presses and Stamping Machinery

- Conveyor Lines and Workstations

- Control Panels and Status Monitoring Systems

- Plant-Wide Emergency Notification Networks

From machine status indication to evacuation signaling, These solutions are tailored to help operations teams quickly identify issues, initiate protocols, and maintain a safe production environment.

Visual Process Indicators for Machine Status and Workflows

In the automotive industry, visual signaling is the preferred solution due to the constant background noise generated by presses, robotic movement, and conveyor lines.

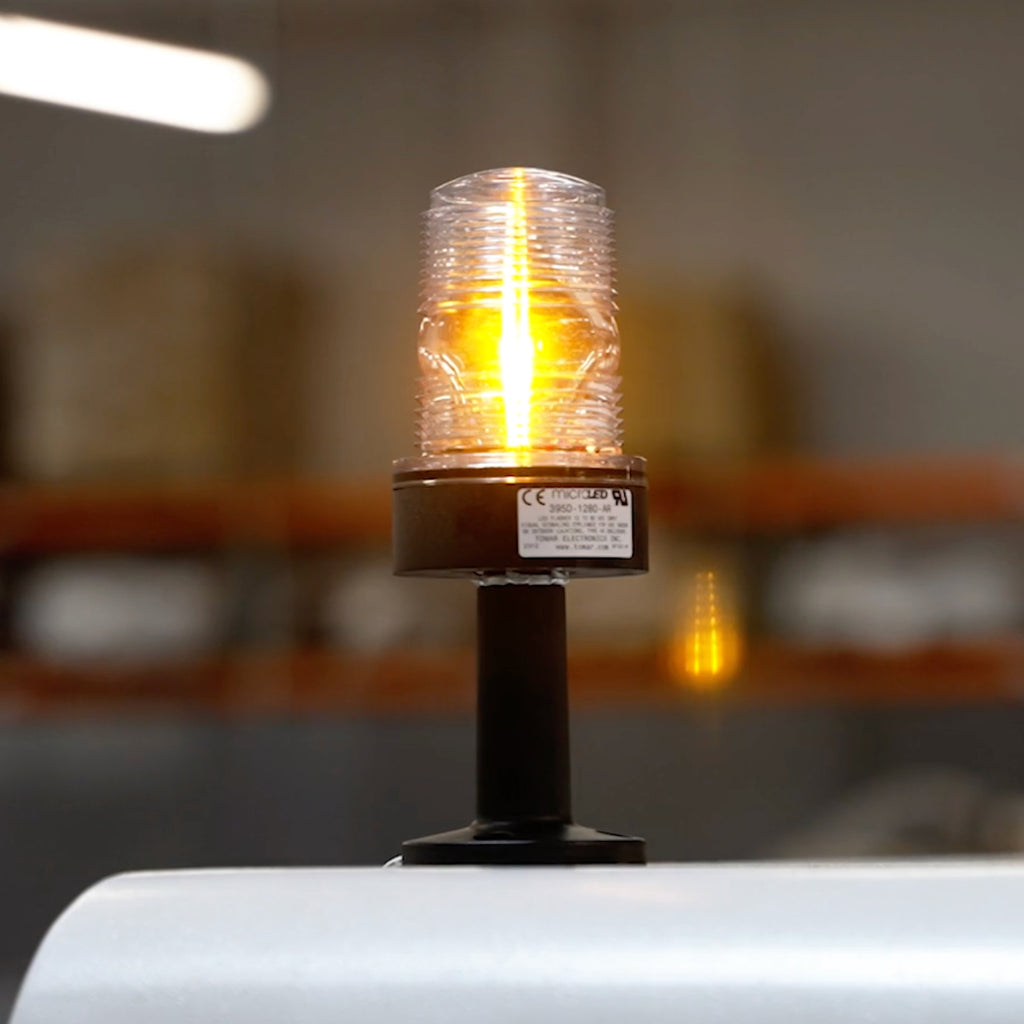

TOMAR’s LED Microstack™ and MicroLED™ indicators are compact visual tools ideal for:

- Machine on/off status

- Tooling change requirements

- Part request signals

- Fault alerts

- Maintenance callouts

These indicators are often mounted on control panels, minimizing wiring and providing real-time status directly where it matters. Using the LED Microstack configurations of 3 or more modules, plant personnel can customize color-coded alerts for multiple status points on a single machine or cell.

When higher visibility is required—especially when operators may have their backs turned—800 Series strobes are used to supplement or replace stack lights. These high-intensity strobes bounce off surfaces and equipment, making them highly effective even in peripheral vision.

Hazardous Area Signaling for Paint and Fuel Systems

Most areas in an automotive plant do not require explosion-proof devices—except for paint booths and fuel depots, where volatile chemicals and vapors pose serious risks. TOMAR offers Division 1 and Division 2-rated signaling devices for these environments, including:

- 1002WEP Power Alarms® for audible evacuation or leak detection signals

- 4375 CID2-rated strobes for highly visible alerts in fume-heavy zones

- Explosion-proof strobes for integration with gas sensors and fire panels

Signaling for Robotics, Presses, and Human-Machine Interaction

Modern automotive production lines rely heavily on robotic automation. These machines often require visual and/or audible indicators to alert personnel during startup sequences, movement, or safety zone breaches.

TOMAR signaling devices used in robotic cells and presses include:

- LED Microstack™ or MicroLED™ units mounted on robot bases

- 800 Series strobes resistant to vibration and mechanical shock

- Audible alerts triggered during robotic motion or abnormal operation

- Control panel indicators for start/stop commands and error codes

In systems with hand or limb detection safeguards, TOMAR’s audible and visual products can be integrated with light curtains or sensor logic to provide real-time alerts during unsafe proximity events.

These products are engineered to resist corrosion, vapor exposure, and high-pressure cleaning—delivering dependable safety in OSHA-classified hazardous locations.

Visual Signaling in High-Noise Industrial Zones

In pressing, stamping, and finishing areas, ambient sound levels often exceed 85-100 decibels. Personnel may wear hearing protection, which further diminishes the effectiveness of audible alarms. Here, visual signaling becomes essential.

TOMAR offers a full suite of high-visibility lighting for these applications:

- 8024 Series strobes for elevated mounting and wide visibility

- 4375L LED strobes for energy efficiency and long service life

- Microstrobe® and MicroLED™ indicators for workstation-level alerts

These devices are designed for high vibration tolerance and long-life performance, reducing maintenance downtime and maximizing uptime.

Engineered Safety and Efficiency for Automotive Plants

Automotive manufacturing plants operate at rapid speeds, with complex machinery and just-in-time production schedules. Safety systems must be scalable, flexible, and robust to keep up.

TOMAR Electronics delivers industrial-grade signaling solutions for:

- Machine status visibility

- Robotic system safety

- Emergency evacuation alerts

- Paint and fuel area compliance

- Material flow and maintenance alerts

From control room panels to plant-wide alarm systems, TOMAR industrial signaling systems ensure your facility is safe, efficient, and compliant with industry standards.

When uptime and safety are mission-critical—TOMAR is your trusted partner in automotive manufacturing.